Overall Update October 2016

So today is the 27th October and as I write this 7903 is tucked up in the shed and already being prepared for her winter maintenance. She has successfully completed the 60 contracted steaming so we are now free to do some of the outstanding tasks as we are not involved with the Santa Season unless a failure of another engine arises.

The screw reverser has literally just been removed and is going to Tyseley in the next few days for overhaul. The reverser whilst not too bad is knocking a bit so Tyseley are going to overhaul it for us. This has never had any attention other than cleaning and painting so Tyseley are going to probably make a new screw thread for it and generally attend to bushes etc. to put it back as new. This will be done and refitted before the end of November, at least that is the plan.

We have a steam leak on the drivers brake valve which has been removed for John Hancock’s attention. Again hopefully this will be a fairly quick job as well.

Mike Strange, a Wednesday gang regular has made two floor cover assemblies for the tender. The problem we had is that coal and coal dust was getting jammed down in the holes where the two water control valve rods disappear through the holes in the tender floor. This resulted in the water handles getting quite stiff. These two cover assemblies have removed that problem so the handles should stay nice and free.

I am talking to Tyseley about coming to Toddington and do some minor fettling on the firebox area as we have a few weeps, nothing very serious but just a bit to tidying up. Dinmore Manor and Foremarke will then have their annual boiler exams by the insurance man just to get them out of the way ready for the 2017 season. Ours will be early but operationally it will suit the GWSR better.

The other major task is to have a go at the Vacuum pump. It is supposed to pump on both strokes but the front valve fails to work. Rather strange as it worked okay when we in traffic before the overhaul. Anyway we are going to recut both valve seats make new valves and set it up as new. However to do that we have designed and had made a special cutter to save us having to remove the pump from the engine. That is in the final stages of being finished.

We also have a mechanical examination to do, plus we want to weigh the engine. We have installed in the internal pit at Toddington some load cells so we are able to weigh engines axle weights. We are then able to adjust them so they are as close to what they should be as possible. It is not a five minute job though.

We have already done some minor cleaning and lapping in of the snifting valves, Drain cocks and other minor bits and bobs purely to keep on top of things.

So all in all plenty to do but a successful first year back in traffic.

You will see elsewhere and via E mail that we have produced a calendar to help raise a bit of money for the engines ongoing support. There are a limited number so if you want one get your order in as soon as possible.

UPDATE - JANUARY 2017

Winter maintenance is now well advanced. A lot of the small jobs have been completed and the steam test is booked for March 3rd.

Tysley have been down and given the firebox the once over to caulk up the weeping seams etc. The firebox should now stay tight.

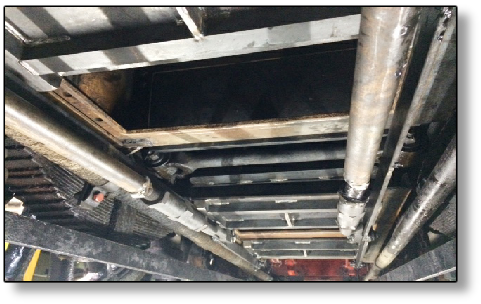

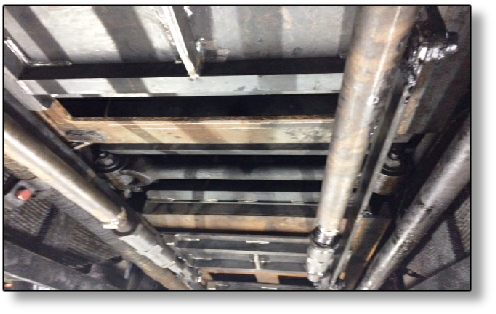

In this winter period we have modified the ashpan further and she now has three sliding hopper doors that allow the ash to simply drop out the bottom of the ashpan. This has been quite a large job but we are hopeful that it will make the end of day process of getting rid of the ash a simple and easy job.

The engine and tender is undergoing a fill B examination and will also have all her axles weighed on the new weighing kit fitted to the internal pit. This may lead to some axle adjustments owing to the weight of steel attached to the ashpan.

The work to the Vacuum pump is now all done. The cutter that John Hancock designed and Dave Mumby made worked an absolute treat. John H then made new valves and the whole thing put together with some faces being lapped in. It will work now!!!!!!

The tender coal space has been given two coats of bitumen to protect it and we will be doing some final painting around the footplate area.

Once all the inspection and winter work is finished we will then do a wash & brush up to get rid of the winter dust and make her ready for the start of the new season!

Generally we are where we need to be at this time of the year but still with plenty to do.

John Cruxon

Locomotive Manager

The new ashpan doors half open and fully open which should make end of the working day somewhat easier